Simply put, air-operated double-diaphragm (AODD) pumps can only operate at peak performance with the right diaphragms installed.

With the largest diaphragm selection and the longest-lasting diaphragm in the industry, Wilden® has the know-how to help you not only select the best diaphragms but also install them correctly.

Below is a brief guide to help you make the most of your diaphragms, which in turn helps you optimize your Wilden AODD pump performance.

Selecting the Right Diaphragms

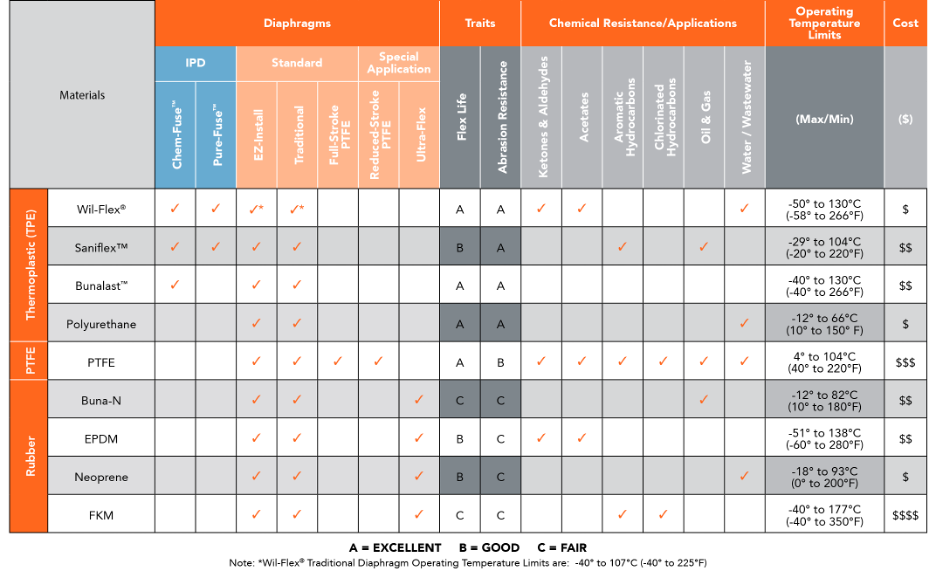

Selecting the ideal diaphragm begins with identifying the appropriate design and material for your product transfer needs. Wilden offers the following diagram designs and materials tailored to meet distinct requirements, excelling across various product transfer applications

The Wilden Chem-Fuse™ Integral Piston Diaphragm (IPD) represents the ultimate in diaphragm innovation. Offering up to 2-3 times longer life (and up to 15x longer in some applications), Chem-Fuse Diaphragms are the longest-lasting diaphragms in the industry. Plus, Wilden Pure-Fuse(™) IPD diaphragms are the ideal solution for food and pharmaceutical applications. They offer clean-in-place (CIP) capability, and superior flow and suction lift over competitor diaphragms.

For more information about every Wilden diaphragm type, click here. You can also check out the following videos for help choosing your diaphragm:

Beware of Pirated Diaphragms

Wilden AODD pumps achieve peak performance only with the use of genuine original equipment manufacturer (OEM) components, including diaphragms. Failure to utilize the correct components may lead to:

- Voided warranty

- Lower flow rates

- More frequent breakdowns

- Reduced operational safety

“Knockoff” companies are pirating pump components, like diaphragms, and selling the unsuspecting components as genuine Wilden parts. However, there is a way to recognize these illegitimate parts. When selecting diaphragms or any other components for your Wilden AODD pumps, look for these warning signs:

- Part numbers that are not typical for the brand

- Missing critical identification stamps

- Parts shipped in non-traditional or atypical packaging.

- Parts that claim to be constructed of a certain material but may not be

- Fake documentation

Read the blog How To Recognize Pirated AODD Pump Parts to learn more about how to avoid the dangers of pirated parts.

Once you’ve selected the right diaphragm for your pump and application, it’s time for installation.

Installing Your Diaphragms

Even an experienced operator should always reference manuals and guides for tips and tricks to help make installation quicker and easier. Wilden offers manuals for its AODD pumps upon purchase and in an online library.

Wilden also offers step-by-step video instructions for installing diaphragms on a 2” Wilden AODD pump, which can also serve as an installation guide for a range of Wilden diaphragms. Click here to watch the video or read the instructions below.

Step-by-Step Installation Guide

Ensure the air side of the diaphragm is facing the inner piston. Place it on the shaft and hand-tighten the outer piston onto it.

Invert the diaphragm and place the shaft into the center section. Rotate the center section and place it in the vise and lock it down.

Place the other inner piston on the shaft and invert the diaphragm. Then, place the outer piston on the shaft and manually tighten it down, using a wrench to secure it.

Use a mallet on the other air section to ensure a full extension on the shaft before seating the diaphragm bead into the bead groove.

With the diaphragm fully seated, attach the chamber and complete assembly on the side of the pump. Rotate the center section to begin working on the other side.

Insert pry bars behind the inner piston to get a full extension. Then, sit the diaphragm into the bead groove and use a mallet to sit the diaphragm into the bead groove.

Attach the spectrum vacuum generator into the inset or outset of the pump (whichever side is accessible) and then engage until the shaft is fully extended.

With the shaft in full extension, invert the diaphragm and insert it into the bead groove. Once the diaphragm is installed, remove the generator from the pump.

Ensure all pump components are secure before operation.

Make Installation Simple with EZ-Install Diaphragms

Unlike traditional AODD diaphragms, Wilden EZ-Install Diaphragms don’t require inverting, which makes them 30% faster to install and helps prevent inadvertent puncturing. Additionally, EZ-Install Diaphragms are 100% compatible with existing hardware and the same price as Wilden traditional shaped diaphragms.

EZ-Install Diaphragms are available in Wil-Flex® (Santoprene®), Bunalast(™) , polyurethane, Saniflex™ and sanitary Wil-Flex® options in 38 mm (1-1/2”), 51 mm (2”) and 76 mm (3”) sizes.

Want to see how Wilden EZ-Install Diaphragms compare to conventional diaphragms? Watch this video. For more information about EZ-Install Diaphragms, visit our product page.

For any information regarding selecting the right diaphragm and its installation process, reach out to a Wilden representative.