Gentle Handling of Shear-Sensitive Materials

Eccentric disc pumps stand out for their exceptional metering capabilities, ensuring precise flow rates and dosing accuracy while maintaining consistent discharge volumes for uniform blending and coating application. Versatile across various viscosities, from low-viscosity solvents to high-viscosity resins, they accommodate diverse formulations such as solvent-based, water-based, and high-solid content systems.

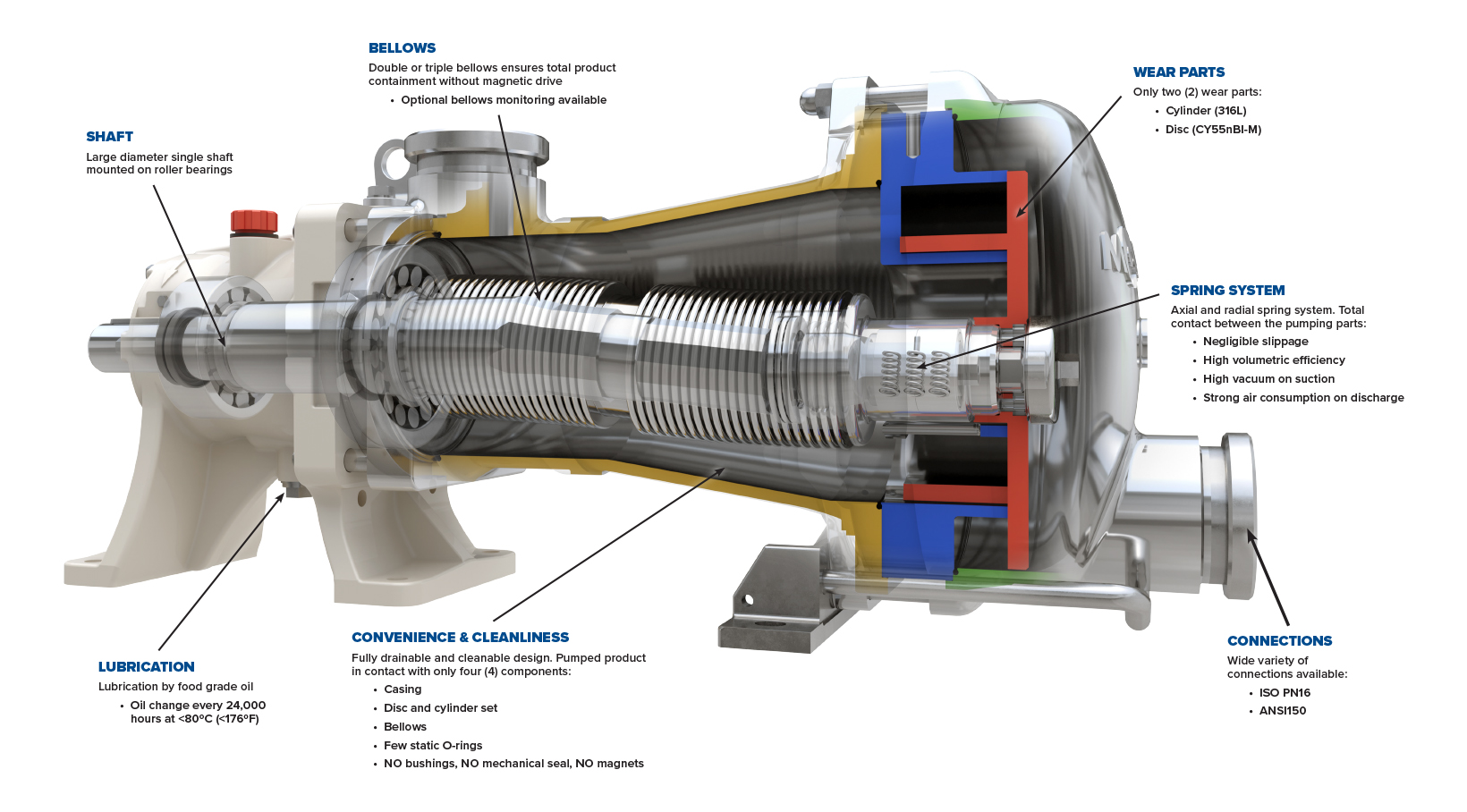

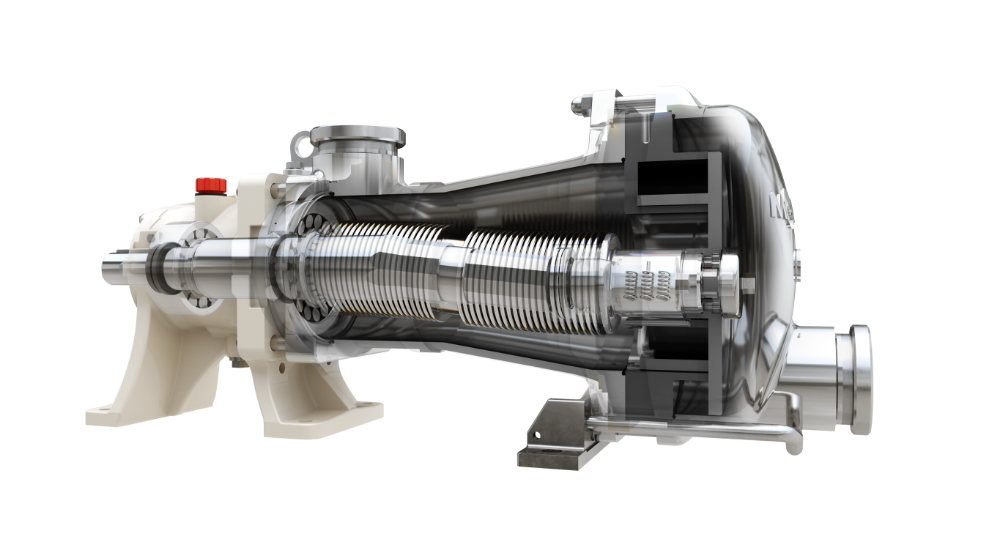

Seal-less Design

The unique seal-less design of eccentric disc pumps ensures durability, safety, and product containment. There are no mechanical seals or bushings in contact with the product, thereby reducing potential leak points, minimizing maintenance requirements, and ultimately enhancing safety.

Consistent / Constant Flow Rate & High Volumetric Efficiency

An eccentric disc pump stands out from most positive displacement pumps as its flow rate remains largely unaffected by changes in viscosity or pressure. This unique feature ensures a consistent flow rate even amidst varying viscosity levels, commonly seen in paints that exhibit pseudoplastic/shear thinning behavior. As a result, tasks like adding additives or performing in-line injections become easier to manage.

Run-Dry Capable

Eccentric disc pumps exhibit the remarkable capability to operate under dry conditions for a duration of up to five minutes without inflicting any harm upon either the pump itself or the overall process in which it is employed, showcasing their resilience and reliability even in adverse operating conditions where lubrication may be temporarily compromised.

Minimal Pulsation & Smooth Control

Eccentric disc pumps provide naturally low pulsation, ensuring a smoother flow profile. Their balanced design reduces pressure fluctuations, eliminating the need for extra dampeners and surge control devices, resulting in consistent material delivery, fewer surface imperfections, and prolonged equipment lifespan.

Line Stripping

With its clean-in-place (CIP) and sterilize-in-place (SIP) design/capability, the same eccentric disc pump can be used for different batches, eliminating the risk of product contamination during changeovers.

All Stainless-Steel Construction

In the absence of stainless steel as the designated standard material, the likelihood of encountering rust-related issues significantly increases, thereby undermining the durability and longevity of the equipment. Additionally, stainless steel not only mitigates rust concerns but also affords additional advantages during chemical cleanup processes.

Reduced Maintenance Requirements

Eccentric disc pumps offer a simpler, sturdier construction with fewer moving parts, reducing maintenance needs and ensuring prolonged service life. Their design mitigates mechanical failure risks and damage from abrasive particles, translating to lower costs, reduced spare parts inventory, and increased uptime for manufacturers in the paint and coatings industry.

High

High

Low

Low