At Quantex, we understand that dispensing highly-concentrated solutions can be very challenging. Higher concentrations often mean higher viscosity fluids, and most pump technologies struggle to transfer thicker liquids. However, product manufacturers are keen to reduce their carbon footprint and one way of doing this is to ship less water, which is not only good for the environment, but it also reduces costs in a number of ways.

In this post, we’ll analyse the benefits that can come from dispensing highly concentrated solutions, and how by doing so, you could reduce your carbon footprint. We will also provide a ground-breaking solution to dispensing higher viscosity fluids and diluting in-pump for a perfectly mixed, ready-to-use consumer product.

Concentrated solutions have been achieved by adding less or removing excess water or other liquids to create a less ‘watered down’ version of the product or solute. Often, this concentrated version will need to be diluted before it is ready for use.

Dilution is the process of adding a diluent (often water) to this concentrated solution. Together, they will then create a product that contains both solvents, but at the chosen ratio.

Therefore, a dilution ratio of 10:1 concentration, is ten times the volume of solvent (usually water) as the volume of concentrate (i.e. fruit juice). Another unit of measurement used for concentrated juices is ‘Brix’. It can be used to calculate the amount of sugar ratio needed to dissolve in water.

Using concentrates and diluting at the point of dispense can bring many benefits to the consumer, especially when compared with pre-packaged goods off the shelf. This is because a dispenser can offer the consumer greater choice – allowing them to tailor the amount of diluent added into their product. These benefits include the opportunity to:

- Reduce the amount of sugar or calories – many food and beverage solutions (e.g. energy, juice or fizzy drinks), are high in sugar or calories. By increasing the dilution ratio, you can reduce the amount of sugar or calories you consume

- Improve the taste – some food and drink products, such as concentrated juices or smoothies, can be too strong or sour to drink for some people, but by adding more dilution, they can be more palatable

- Make the product easier to digest – some people struggle to consume thick and heavy products as they are difficult to digest, but diluting them can make consumption easier

- Reduce the risk of side effects – There are a few food and drink products that are enjoyable but can come with negative side effects (e.g. energy drinks can cause anxiety, insomnia, and headaches), but by diluting them, you can reduce the risk of these side effects.

Next, we’ll consider the further benefits that come with packaging and shipping a smaller product that helps reduce your carbon footprint and transportation costs:

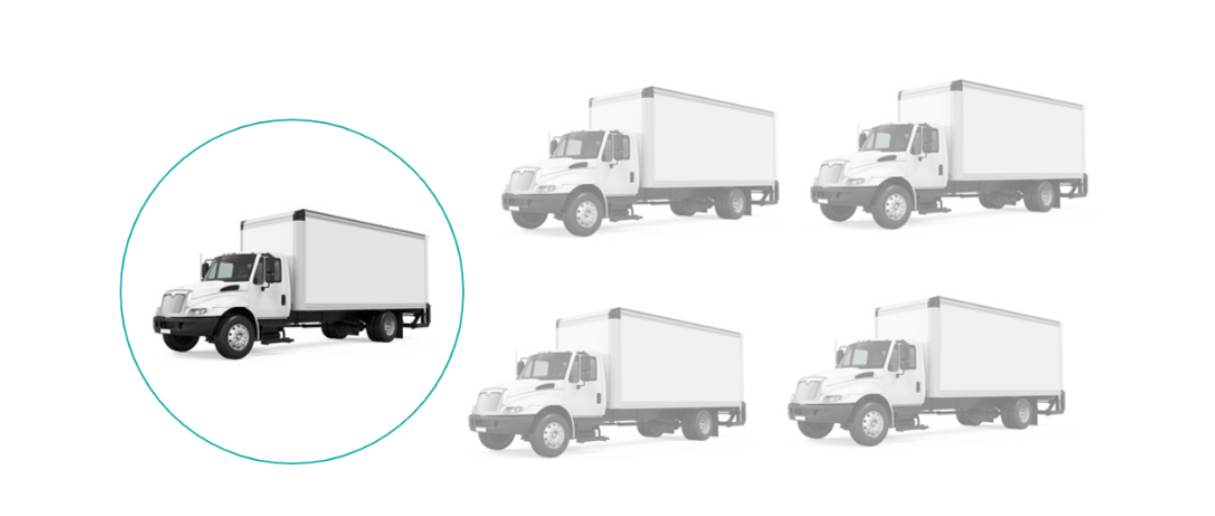

- Reduce the size of transportation – as a concentrated solution is smaller per serving, the volume needed to ship can be smaller meaning the transportation, its emissions and its carbon footprint can be reduced

- Increasing the product shelf life – by reducing or removing the solute that makes the composition of a product start to decompose or rot, you can prolong the shelf life of your product

- Reducing the amount of packaging needed during transportation – by shipping a smaller-sized product, the packaging size can be reduced, along with the protective shipping materials and waste produced at the end of transportation or the product’s life

- Smaller vehicles can be used to transport the product – by transporting a smaller and lighter product, you reduce the amount of energy required for shipping and transportation which can help to reduce the emissions associated with transportation and packaging

- Reduction in the amount of energy to maintain the product – through using a more concentrated solution, you don’t need as much heat or cooling to maintain the temperature of the product to keep it within its best conditions

- Reduced loading costs – as the product is smaller, the costs required to transport the product will be reduced, for example, a smaller product could be considered a ‘fast-loader’ as it’s easier to transport and will therefore cost less than a bigger, bulkier product

- The ability for consumers to reuse containers – when the solution is diluted at the point of dispense, this presents the opportunity for consumers to reuse their bottles or containers, saving the amount of plastic waste generated

- Smaller shelf requirements – where the final product is diluted using water, the feed can be plumbed in directly and stored elsewhere meaning the water doesn’t need to be right next to the pump and solution, taking up less space or shelf surface

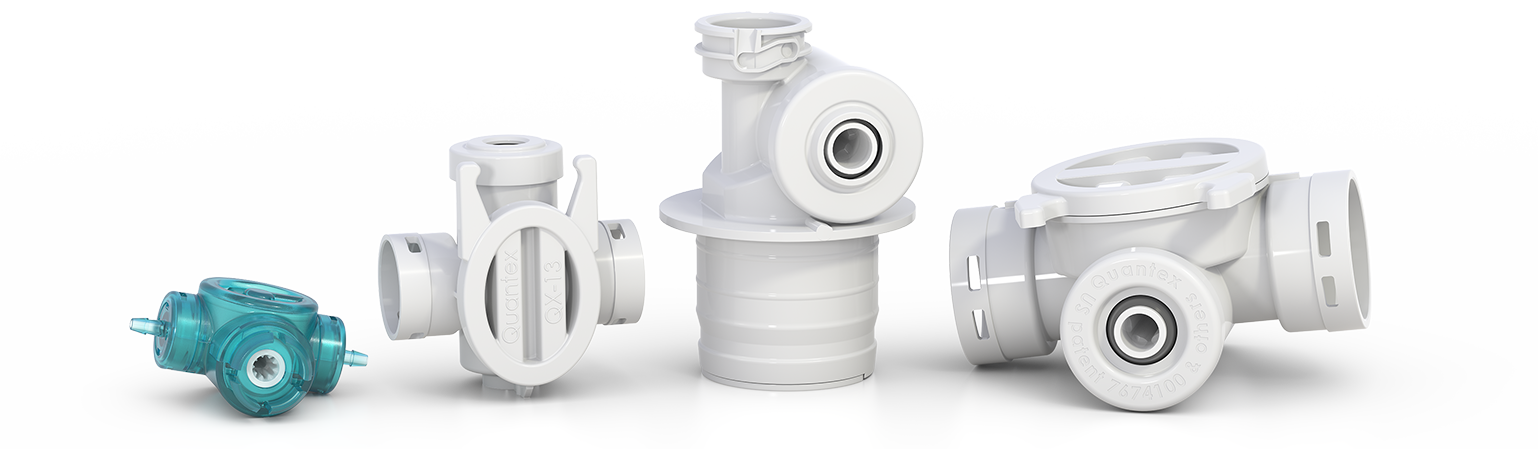

So, there are many commercial drivers for using higher concentrations, but as already mentioned, there is a limit to how viscous a product can be due to the limitations of a dispenser’s pump capability. With Quantex, however, far higher concentrations are possible due to the pump’s unique high vacuum and high pressure capability, which means that Quantex can transfer viscosities up to 100,000cP (which is roughly the consistency of a thick hair conditioner or sour cream) so thick syrups, for example, are entirely possible.

Quantex offers a unique system because its pumps are designed for single-pack use and are combined with and replaced with each new liquid pack. So, rather than having a pump in the fixed equipment that needs to be cleaned and calibrated from time to time, the pump and pack contain and dispense the product directly from its primary container, thus eliminating the need for costly cleaning and maintenance. This also enables rapid product replenishment and products can be swapped in and out of the same channels without cross-contamination. This is perfect for dispensing products in retail environments where shop-floor staff are not accustomed to having to maintain time-consuming dispense equipment.

Quantex offers Dilution versions of its pumps where the pump features an extra inlet for the diluent (usually a regulated, filtered mains water supply). The water and concentrate are mixed inside the pump to produce a final product with no stratification. Depending on the final solution, the solute can be diluted at different ratios to achieve different products or variations in tastes.

The below video shows an example of a Quantex recyclable pump dispensing concentrated juices at various dilution ratios with the addition of accurately dosing additional raspberry notes.

This second video below shows detergent being dispensed at a variety of different ratios which is achieved by simply changing the speed at which the motor is running the pump. In this video you will see that the pump has been programmed to reverse cycle for a couple of turns of the rotor at the end of the dispense. This helps to eliminate drips and provide a clean dispense.

Quantex pumps are suitable for use in a variety of industries from refill dispensers in supermarkets, to food and beverage transfer in food service environments, hotels and offices, or in manufacturing and consumer and industrial applications.

By transporting your product in a concentrated form and using a Quantex pump, you can dilute in-pump with a ratio of up to 500:1. This equates to removing 80 – 99% of the water from the distribution channel which (in some cases) is the equivalent of reducing the transportation from five vehicles to just one, creating a massive reduction in shipping costs and transportation emissions.

There are many benefits to working with concentrated solutions and then diluting them at the final destination. With a range of pumps that can dispense virtually any liquid you can find in a supermarket, restaurant or retail environment – including viscous products like mayonnaise, spreads, viscous concentrates, and thick hair conditioner, or aggressive fluids like bleach – our range of recyclable Quantex pumps provide retailers with a convenient, easy to use, hygienic pumping system with quick product changeovers, no cleaning, no calibration and accurate, drip-free dispensing.

With the aid of a Quantex pump, you can easily dispense highly concentrated solutions to improve your product offering, as well as reduce your wastage, transportation and related costs. If you are looking for ways to reduce your carbon footprint, consider using highly concentrated solutions. It is a small change that can make a big difference.

You can learn more about our pump range here:

If you’d like to learn more or discuss how a Quantex pump could work for you, please email quantex-info@psgdover.com or call +49 (2065) 89205-0.