The world of beauty and body care is

constantly evolving, seeking new methods and manufacturing techniques to

improve efficiencies, enhance the customer experience, save single-use

packaging waste, and cater to individual customer needs. In this blog,

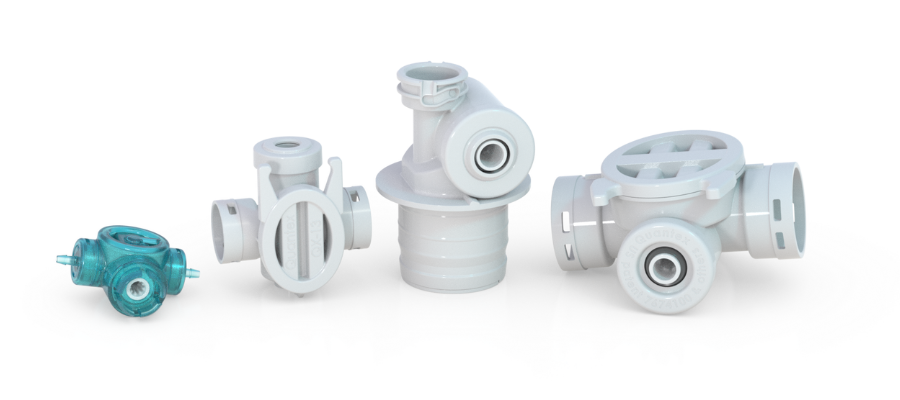

we’ll explore how Quantex’s game-changing pump technology can provide a

radical new hygienic, easy-to-use, cost-saving and sustainable pumping

solution that could impact the beauty industry in a number of ways.

Transferring Thick and Viscous Solutions

One of the biggest challenges the beauty industry faces is understanding and being able to handle highly viscous products like thick hair conditioners, face creams, and body butters.

Traditional peristaltic pumps struggle with these thick products because they can’t cope with the pressure and flow rate needed to propel the produce out of its primary container and into its intended location. This failure can lead to manufacturing inconsistencies and inefficiencies such as a poor quality product or an inaccurate quantity ready for sale. Quantex, however, has developed a range of pumps specifically designed to handle thick and viscous materials with ease by using a positive displacement rotary action, with high vacuum and high-pressure capability.

Accurate Dosing: A Drop of Perfection

The beauty industry is full of expensive and luscious products that require careful handling and a delicate balance of ingredients to make their final solution. If these expensive ingredients aren’t accurately dosed or mixed at the right stage, the product composition will be inaccurate and could be costly to rectify, especially when produced in mass volumes.

However, dispensing the perfect amount of product is made far easier with Quantex pumps due to their unique method of precision pumping. The fixed displacement pump design principle consists of the volume of an individual cavity of liquid product carried on the rotor constrained within the rigid pump housing. This ensures that an accurate volume of liquid is displaced for each revolution over a wide range of flowrates, pressures, viscosities and temperatures.

One way to revolutionise the beauty industry is to mix these ingredients at the point of dispense. An example of this could be a body cream manufacturer who needs to mix small but highly accurate fragrances into the final solution to create a range of scented body lotions. The base mixture remains the same, but the additional scent that’s added at the end needs to be perfectly balanced to create the right notes and fragrance. This can be achieved with Quantex’s fixed displacement rotary action and in-pump dilution and mixing.

Hygienic, Easy-to-Use, Compact Dispensing

Another unique attribute to Quantex pumps is that they are designed to be recyclable and for single-pack-use. The pump is attached directly to the product’s primary container and dispensed directly from the container through the pump, therefore no product needs to travel through fixed machinery. Products can easily be swapped in and out of any channel with one click, and without cross-contamination. With only a standard motor-drive and motor controller required, dispensing machinery can be highly compact and low cost. Since the pumps are replaced with each new pack, no calibration is required which creates a very low-maintenance system.

Colour on Demand: A Customised Experience

Beauty product companies are always looking for ways to stand out, and one way to do so is to provide more bespoke choices for customers. The world is full of different bodies and unique looks, so how can we provide customisable products?

Make-up brands are only just starting to tap into the customisation market, such as No 7 who provides onsite or virtual ‘colour-matching’ services that will scan the customer's skin colour, pick up the tone of pigments on the skin and then suggest the closest matching foundation they have out of their pre-made solutions. This bespoke service could be augmented with the aid of Quantex pumps; by accurately mixing the colour pigments into base products within a dispensing machine at the point of sale. This can produce the exact unique shade/formula to match the skin-type on demand and consumers will benefit from their own special uniquely-colour-matched foundation.

Beyond the Bottle: Refill and Sustainability

As the world becomes increasingly aware of sustainability and the impact of excessive packaging, the beauty industry and its customers are finding ways to reduce their waste. Zoe Boikou, CEO and founder of Zoeva notes that in 2024 “consumers will have an even stronger focus on products that are reusable and recyclable.” As one of the biggest contributors to waste, “the beauty industry will need to continue to innovate when it comes to the life-cycle of products” quotes Forbes.

Companies such as The Body Shop and Lush are already paving the way for this. Lush, acknowledges that in 2022, its customers returned and refilled over 720,000 items of Lush packaging to their shops for product refill and even offers customers incentives through its ‘Bring It Back recycling scheme’ to encourage recycling and refilling.

Quantex pumps can align perfectly with the growing trend of refillable beauty products and help brands integrate cost-effective, hygienic and easy-to-use refill stations within their retail environments. Ideal for handling thick solutions and providing accurate dosing, Quantex pumps are a key enabler to help the beauty industry reduce packaging waste.

Reduced Transportation Costs and Carbon Footprint

As mentioned in a previous blog ‘How to dispense highly concentrated solutions to reduce your carbon footprint’ we discussed the benefits of working with highly concentrated liquids and how this means products can be shipped in smaller, more concentrated versions, resulting in a reduction in transportation costs. There are many beauty products that lend themselves to higher concentrated versions: for example:

- Serums

- Toners

- Perfumes

- Shampoo

- Nail polish remover

- Hand-creams

- Conditioners

Certain products such as hand creams and conditioners could be available with various thickness options depending on the amount of water added to the concentrated base product.

Quantex pumps are known for working with far higher concentrations than most pumps due to the pump’s unique high vacuum and high-pressure capability – and using In-Pump Dilution versions open up the possibilities for using highly concentrated products to save brand’s shipping costs and carbon footprints.

Handling Expensive Ingredients in Small Quantities

The beauty industry is known for providing solutions in compact packaging. Dispensing these products in such small quantities into mini containers can be tricky, but Quantex Low-Flow and Microdosing Pumps are perfect for handling precise doses of solutions into small and narrow containers or pots.

Summary

Quantex pumps are poised to revolutionise the beauty industry in a number of exciting ways… Their ability to handle high-viscosity products, dispense precisely, hygienically, and without mess are all compelling attributes – but considering, in addition, that they render more compact and low-cost dispensers, that are easy-to-use and maintain, and that they can dilute concentrates in-pump, and you have a number of exciting opportunities to move the beauty industry forward for the better.

For example to enable:

- cost effective in-store refill machines to save single-use packaging waste

- future technologies like facial-scanning bespoke make-up colour-mixing to provide consumers with more choice and encourage brand loyalty

- dispensing concentrated products that take water out of the distribution channel and lower shipping costs and carbon emissions.

In conclusion, Quantex is set to pave the way for a more personalised, efficient, and sustainable future for beauty. So, get ready to witness some transformations, where Quantex pumps become the silent heroes behind some radical changes for the better for the beauty industry.

You can learn more about our pump range here:

If you’d like to learn more or discuss how a Quantex pump could work for you, please email quantex-info@psgdover.com or call +49 (2065) 89205-0.