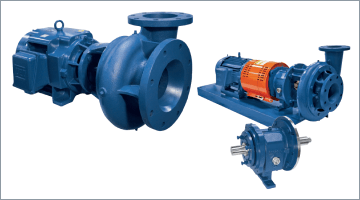

Close-Coupled or Frame-Mounted Configurations

850 Series pumps are provided with NEMA JM or JP close-coupled motors. As an alternative, Griswold offers flexible couplings to electric motors, including open drip-proof, totally-enclosed and explosion-proof motors, or engine, steam turbine, and belt-driven options.